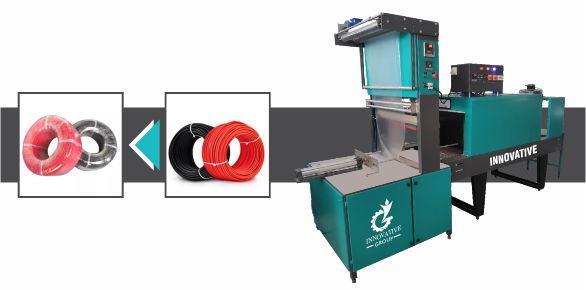

We are presenting fine quality Shrink Wrapping Machine Wire & bundle with Manual Collation and with partial ‘U’ sealer. These products are developed from the best available technology.

Range:

- Products such as a battery, bottles, tins, cans, boxes, containers, which are available in numerous configurations of 6, 12, 18 or 24 with/without a base tray or with the help of FLAT SHEET at the bottom, could be shrunk wrapped at various speeds of 5-15 packs per minute

- stretch wrapping Similarly stretch packing After that product good looking In addition, I’m recording some video for stretch wrapping machine

Complete Guide to Shrink Wrapping Machine for Wire & Bundle – Innovative WrapTech Pvt. Ltd.

What is a Shrink Wrapping Machine for Wire & Bundle?

The Shrink Wrapping Machine for Wire & Bundle is an industrial-grade packaging solution specifically designed to wrap wires, cables, and small product bundles securely using shrink film. It ensures uniform, protective, and professional packaging while significantly improving efficiency compared to manual wrapping.

This machine uses heat-activated shrink film to tightly encase the products, providing protection from dust, moisture, and handling damage. By automating the process, it reduces labor, minimizes material waste, and enhances overall production reliability.

How the Machine Works: Step-by-Step Technical Operation

Product Placement: Place the wire coils, cable bundles, or small product bundles on the machine’s infeed platform or conveyor.

Film Feeding: The machine automatically positions the shrink film around the product. Depending on the model, operators may manually adjust film placement for irregular-sized bundles.

Sealing: Sealing jaws or bars cut and seal the film around the bundle. Temperature-controlled heating ensures a strong, uniform seal without damaging the product.

Shrink Process: The sealed bundle passes through a shrink tunnel or receives hot air from a shrink gun. Controlled heat causes the film to contract tightly around the bundle, creating a compact and secure wrap.

Product Discharge: Once wrapped, the bundle exits the tunnel onto the outfeed area or conveyor, ready for storage or shipping.

Key Notes:

PLC-based control systems allow precise adjustments for different wire diameters and bundle sizes.

Sensors detect product placement to prevent misalignment and reduce film waste.

Importance and Advantages in Modern Industrial Operations

High Productivity: Wraps large volumes of wire and bundles faster than manual methods.

Uniform Quality: Ensures consistent packaging that maintains professional standards.

Material Efficiency: Reduces shrink film wastage through precise heat and tension control.

Enhanced Protection: Protects wires, cables, and bundles from dust, moisture, and mechanical damage during storage and transport.

Labor Reduction: Minimizes manual intervention, freeing staff for other production tasks.

This machine delivers reliable, cost-effective, and scalable packaging in industries where high-volume wire or bundled product handling is required.

Standard Industry-Level Technical Specifications of Wire Bundle Shrink Wrapper

Power Supply: 220V / 380V, 50/60 Hz (3-phase for heavy-duty models)

Shrink Tunnel Temperature: 0–250°C adjustable

Machine Speed: 5–30 bundles/minute (model-dependent)

Conveyor Length: 1–5 meters (customizable)

Machine Dimensions: 2000 x 800 x 1200 mm (approx.)

Machine Weight: 150–400 kg depending on model

How to Choose the Right Wire Bundle Shrink Wrapper

Consider These Factors:

Production Capacity: Match machine speed to daily output requirements.

Material Compatibility: Ensure machine handles your shrink film type (PVC, polyolefin, polyethylene).

Automation Level: Semi-automatic for smaller operations, fully automatic for high-volume lines.

Bundle Size: Choose a tunnel or sealing mechanism suitable for your wire diameters and bundle dimensions.

Budget: Balance upfront cost with long-term savings in labor, material, and efficiency.

FAQs

Q1: Can this machine wrap thick wire bundles?

A1: Yes, models with larger tunnel sizes and adjustable heat settings can handle thick wire and cable bundles.

Q2: Can it handle multiple bundles simultaneously?

A2: Fully automatic and rotary wrapper models can wrap multiple small bundles in a single cycle.

Q3: Which shrink films are compatible?

A3: PVC, polyolefin, and polyethylene films are supported, with temperature adjustments for optimal shrinking.

Q4: How does it prevent bundle damage?

A4: Controlled heat, adjustable conveyor speed, and tension control protect delicate wires from deformation or melting.

Innovative WrapTech Pvt. Ltd. provides high-performance Shrink Wrapping Machines for Wire & Bundle that maximize productivity, reduce waste, and ensure safe, consistent packaging for industrial applications. Choosing the right model and following operational best practices ensures optimal performance and long-term reliability.