Orbital type stretch wrapping machines are ideal for long loads that can not be stretch wrapped on a conventional turntable or rotary tower type machine.

Examples of products that are well suited for orbital wrapping pipe, plastic extrusions, carpet rolls, lumber, aluminum siding, and many other long products.

Ring sizes from 15 inch to 90 inch are available to accommodate virtually all orbital wrapping applications.

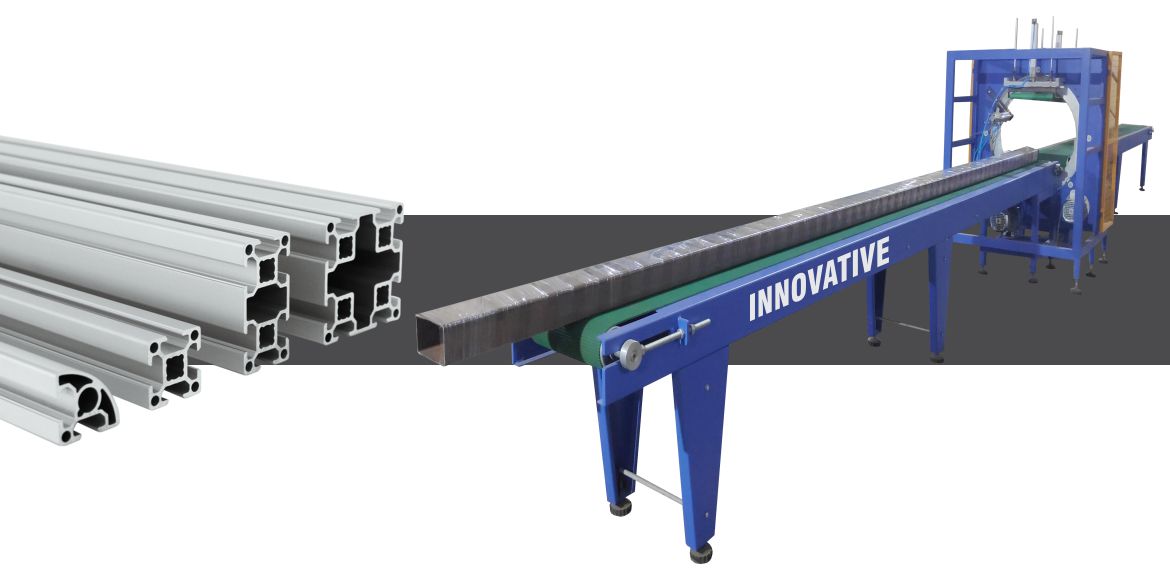

Aluminium Profile Packing Machine

An Aluminium Profile Packing Machine is industrial equipment designed to automate the packing, bundling, and wrapping of aluminium profiles into protective packages for storage, transport, and shipment. These machines reduce manual labor, ensure uniform packaging, and protect profiles from scratches, dents, or corrosion during handling and logistics.

How It Works: Step-by-Step Process

Loading the Profiles: Operators place aluminium profiles onto the conveyor or loading platform. Profiles can be single pieces or pre-bundled sets.

Alignment & Positioning: The machine aligns the profiles automatically to ensure uniform orientation and spacing. Sensors detect misalignment and adjust positions.

Strapping or Wrapping: The machine applies protective packing materials, such as shrink film, stretch wrap, or strapping bands, around the profiles.

Sealing or Heat Shrinking: If shrink film is used, the machine applies heat to seal and tightly wrap the profiles. For strapping machines, a tensioning mechanism secures the bands.

Labeling & Coding (Optional): Some machines can print labels or codes for inventory tracking.

Output & Stacking: Packed profiles move to the discharge area, ready for storage or transport. Automated systems can stack bundles on pallets.

Types and Variants

Manual Aluminium Profile Packing Machine

Operator manually loads profiles; machine assists in wrapping or strapping.

Use: Small workshops or low-volume operations.

Advantage: Low investment cost.

Semi-Automatic Packing Machine

Operator feeds profiles; machine handles wrapping, sealing, and strapping.

Use: Medium-scale production lines.

Advantage: Balances cost and efficiency.

Fully Automatic Packing Machine

Machine handles loading, alignment, wrapping/strapping, sealing, labeling, and stacking with minimal operator intervention.

Advantage: Maximum speed, consistency, and labor savings.

Heat Shrink Packing Machine

Uses heat to tightly wrap profiles in shrink film.

Use: Aluminium profiles prone to scratches during transit.

Advantage: Provides protective sealing and moisture resistance.

Stretch Wrap Packing Machine

Wraps profiles with stretchable plastic film.

Use: Light to medium protection and flexible bundling.

Advantage: Faster operation and lower cost than shrink wrapping.

Strapping/ Banding Machine

Use: Heavy or long profiles requiring rigid bundling.

Advantage: Excellent stability for stacking and transport.

Key Technical Features and Operational Benefits

| Feature | Benefit |

|---|---|

| Automatic profile alignment | Ensures uniform packing, reduces damage |

| Adjustable wrapping tension | Prevents profile deformation |

| PLC/Touchscreen control | Easy operation and quick changeovers |

| Multiple packing modes | Supports shrink, stretch, or strapping methods |

| Conveyor integration | Seamless workflow with production lines |

| Safety sensors | Prevents accidents and machine damage |

| Labeling integration | Supports inventory tracking and logistics |

How to Choosing the Right Model

Buyers should consider:

Capacity: High-volume operations require fully automatic machines.

Profile type: Long, heavy profiles may need strapping machines; delicate profiles may need shrink wrapping.

Automation level: Semi-automatic for medium-scale; fully automatic for large-scale operations.

Budget: Manual or semi-automatic machines are cost-effective; fully automatic offers ROI through labor savings.

Integration: Check if the machine integrates with your production line or warehouse automation.

Conclusion:

The Aluminium Profile Packing Machine is a vital industrial asset that saves labor, ensures product safety, and accelerates packaging processes. By selecting the right type and size, aligning with your production volume, and following proper operational practices, businesses can significantly improve efficiency, reduce losses, and enhance product quality.

Frequently Asked Questions (F&Q)

Q1. What products can an aluminium profile packing machine pack?

An aluminium profile packing machine is designed to pack aluminium extrusions, profiles, sections, frames, channels, and long metal components used in construction and industrial applications.

Q2. How does an aluminium profile packing machine work?

The machine wraps stretch film or shrink film around the aluminium profiles using controlled tension or heat, ensuring uniform protection against scratches, dust, and moisture during handling and transportation.

Q3. Which packaging materials are compatible with this machine?

Depending on the model, the machine supports LLDPE stretch film, LDPE shrink film, and protective wrapping materials customized to surface finish requirements.

Q4. Can the machine handle different profile lengths and cross-sections?

Yes. Adjustable conveyors, guides, and wrapping parameters allow the machine to handle various aluminium profile lengths, widths, and shapes.

Q5. Is this machine suitable for continuous industrial operation?

Yes. Aluminium profile packing machines are built with heavy-duty components and are suitable for continuous production environments with routine maintenance.