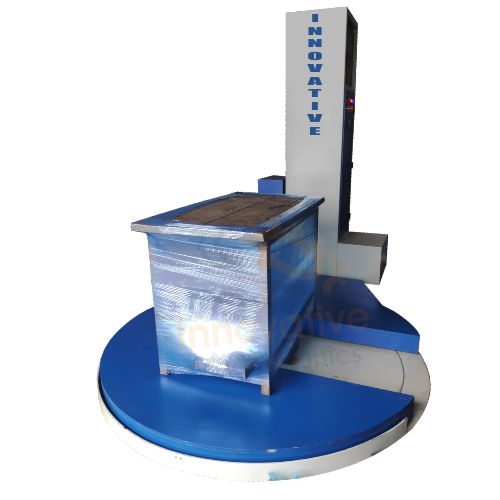

Arm Type Pallet Wrapper

An Arm Type Pallet Wrapper is an advanced pallet wrapping machine that wraps loads using a rotating mechanical arm while the pallet remains stationary. Unlike turntable pallet wrappers, this system eliminates pallet rotation, making it ideal for heavy, unstable, oversized, or high-value pallet loads.

Manufacturers use an Arm Type Pallet Wrapper where floor-mounted turntables cannot safely handle pallet weight or load geometry.

Why This Machine Is Important in Modern Industrial Operations

Modern logistics and production environments demand speed, safety, and load stability. Rotating heavy pallets increases risk and limits productivity.

An Arm Type Pallet Wrapper:

Wraps heavy pallets without rotating the load

Handles unstable or tall products safely

Improves wrapping speed and consistency

Reduces stress on pallet bases and products

Enhances operator safety

This machine supports high-throughput operations in manufacturing, warehousing, and export packaging.

How to Choose the Right Arm Type Pallet Wrapper

1. Load Capacity and Dimensions

Select a machine based on pallet weight, height, and footprint. Arm type systems handle very heavy loads efficiently.

2. Product Material

Fragile cartons, bagged goods, bottled products, and irregular loads benefit from stationary pallet wrapping.

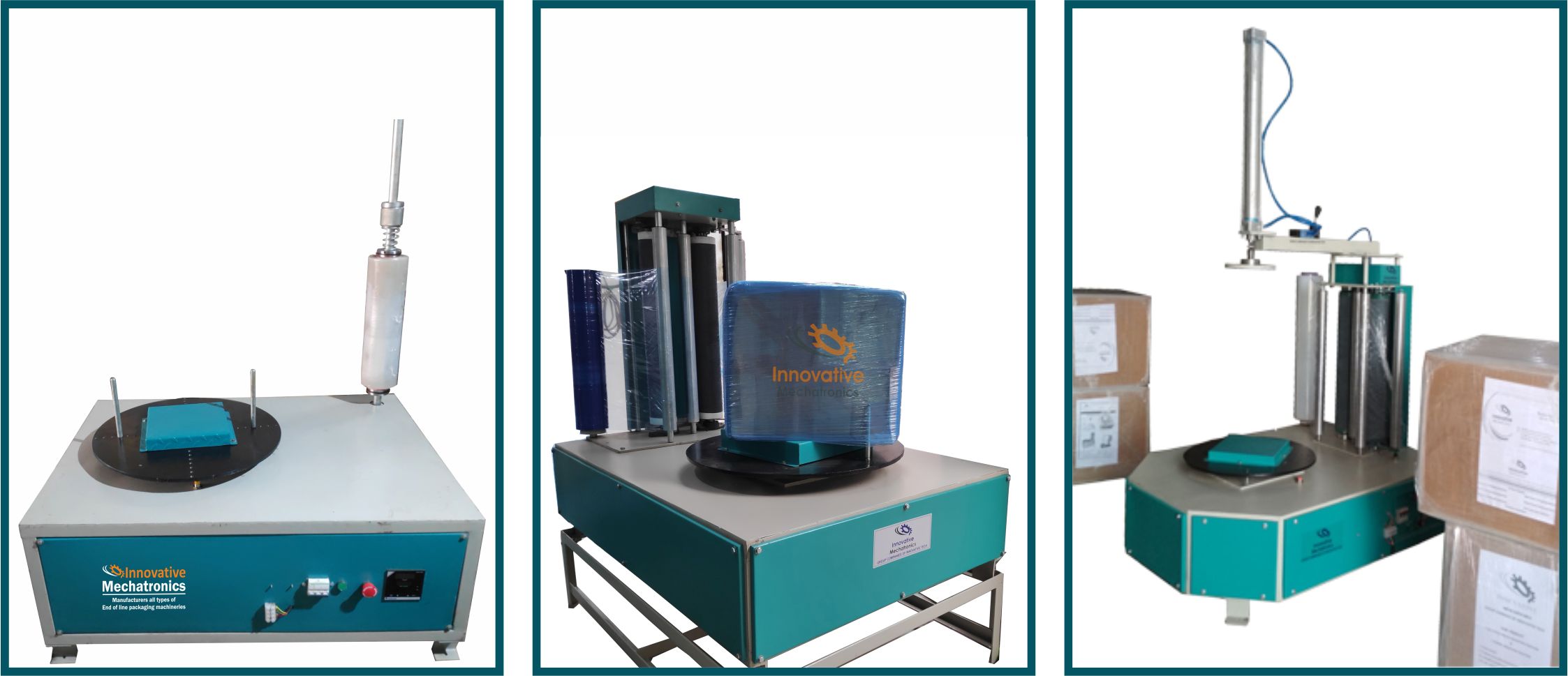

3. Automation Level

Semi-automatic models suit medium-volume operations

Fully automatic Arm Type Pallet Wrappers suit high-speed lines

4. Budget and Long-Term ROI

Although the initial investment is higher, reduced damage and higher uptime deliver strong long-term returns.

Innovative WrapTech Pvt. Ltd. helps customers select machines based on real load behavior and workflow needs.

Safety Standards, Compliance, and Operator Protection

Arm Type Pallet Wrappers from Innovative WrapTech Pvt. Ltd. include advanced safety systems:

Emergency stop buttons

Controlled arm rotation speed

Safety fencing or light curtains

Electrical overload protection

Operator-friendly control panels

These features ensure compliance with industrial safety regulations and protect personnel.

Why Manufacturers Prefer Professional-Grade Machines

Manufacturers choose professional Arm Type Pallet Wrappers because they:

Operate reliably under continuous industrial use

Maintain consistent film tension and coverage

Handle heavy and unstable loads safely

Meet export and logistics safety standards

Low-quality machines increase risk and reduce operational efficiency.

Frequently Asked Questions (FAQ)

Q1. When should I choose an Arm Type Pallet Wrapper?

Choose it when pallet loads are heavy, unstable, tall, or unsuitable for turntable rotation.

Q2. Does the pallet move during wrapping?

No. The pallet remains stationary while the arm rotates around it.

Q3. Which stretch film works best?

Standard LLDPE stretch film works best for most applications.

Q4. How many operators are required?

One operator can manage semi-automatic systems. Automatic machines need minimal supervision.

Q5. Is this machine suitable for automated lines?

Yes. It integrates easily with conveyors and pallet handling systems.

An Arm Type Pallet Wrapper provides a safe and efficient solution for wrapping heavy and unstable pallets. It improves productivity, enhances safety, and ensures consistent packaging quality.

Innovative WrapTech Pvt. Ltd. designs Arm Type Pallet Wrappers engineered for industrial durability, operator safety, and long-term performance.