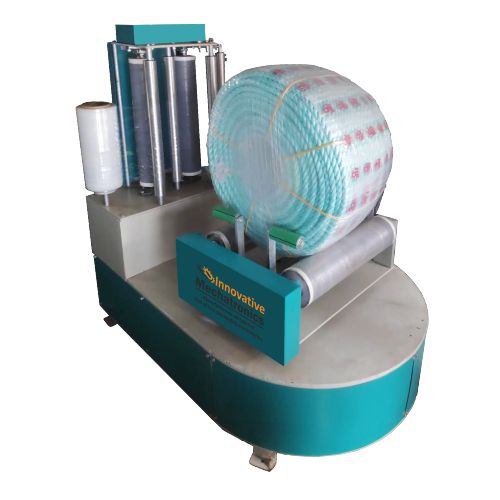

Paper Roll Stretch Wrapping

Paper Roll Stretch Wrapping is an industrial packaging solution designed to securely wrap paper rolls using stretch film with controlled tension. The machine rotates or orbits around the paper roll and applies a uniform, tight wrap that protects the roll edges and surface from moisture, dust, and handling damage.

Innovative WrapTech Pvt. Ltd. designs this system specifically for paper mills, printing houses, and converting plants that handle heavy and sensitive paper rolls.

Why Is This Machine Important in Modern Industrial Operations?

Paper rolls are vulnerable to edge crushing, moisture absorption, and contamination. Manual packing cannot provide consistent protection at high production speeds.

A Paper Roll Stretch Wrapping machine:

Protects paper edges from crushing and deformation

Prevents moisture, dust, and dirt exposure

Maintains roll shape during storage and transport

Improves packing speed and consistency

Reduces labor dependency and packaging waste

This machine ensures smooth downstream processing and minimizes material loss in modern industrial operations.

How to Choose the Right Paper Roll Stretch Wrapping Machine

1. Based on Capacity

Select a machine that matches your production output:

Low to medium volume: Semi-automatic stretch wrapping systems

High-volume lines: Fully automatic or PLC-controlled machines

Choosing the right capacity eliminates bottlenecks and supports future expansion.

2. Based on Paper Roll Material and Size

Different paper grades require precise wrapping control:

Kraft and board rolls: Higher tension and reinforced wrapping

Tissue and coated paper: Gentle tension with surface protection

Wide or jumbo rolls: Heavy-duty rollers and rigid machine frames

Innovative WrapTech machines offer adjustable tension and wrapping programs.

3. Based on Automation Level

Semi-Automatic Machines: Suitable for varied roll sizes and flexible production

Fully Automatic Machines: Ideal for continuous lines with minimal operator involvement

Automation improves consistency and reduces handling damage.

4. Based on Budget

Professional machines deliver long-term ROI through:

Reduced paper damage and rejection

Lower film consumption

Faster packaging cycles

Minimal maintenance and downtime

Avoid low-cost machines that compromise paper protection and durability.

Safety Standards, Compliance, and Operator Protection

Innovative WrapTech Pvt. Ltd. designs machines to comply with industrial electrical and mechanical safety standards.

Key safety features include:

Emergency stop systems

Safety guards and protective covers

Controlled speed and film tension

Industrial-grade electrical components

Ergonomic control panels

These features ensure safe operation while maintaining high productivity.

Why Manufacturers Prefer Professional-Grade Machines

Manufacturers choose Innovative WrapTech Pvt. Ltd. because professional-grade machines provide:

Precision wrapping for sensitive paper materials

Consistent packaging quality across shifts

Customization for roll diameter, width, and weight

Reliable performance in demanding industrial environments

Professional machines protect product quality and brand reputation.

Frequently Asked Questions (FAQ)

1. What types of paper rolls can this machine wrap?

The machine wraps kraft paper, tissue paper, coated paper, board, and jumbo paper rolls.

2. Does stretch wrapping damage paper edges?

No. The machine applies controlled tension that protects edges without crushing or marking the paper.

3. Is this machine suitable for export packaging?

Yes. It provides moisture-resistant, stable wrapping suitable for long-distance and international shipments.

4. How much labor does the machine save?

One operator can manage the wrapping process, reducing labor requirements by up to 60%.

5. Can the machine handle different roll sizes?

Yes. Innovative WrapTech Pvt. Ltd. offers adjustable and customized machines for various roll diameters and widths.