What Is an Industrial Reel Roll Wrapper?

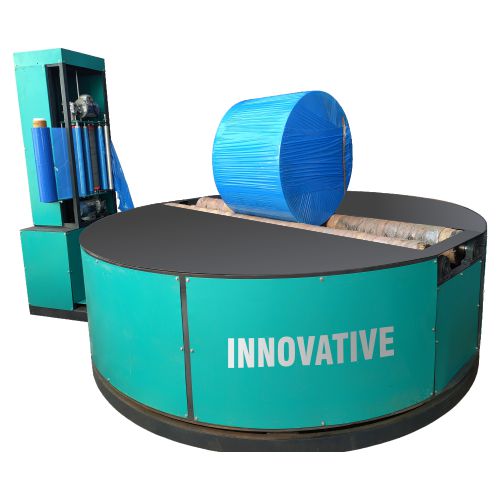

An Industrial Reel Roll Wrapper is a mechanized packaging system that securely wraps cylindrical reels and rolls—including paper reels, plastic film rolls, textile rolls, aluminum foils, and nonwoven materials—using stretch film or protective wrapping material.

The machine applies controlled, uniform wrapping tension around the reel surface and edges, ensuring protection against dust, moisture, abrasion, deformation, and transit damage. Manufacturers use reel roll wrappers to standardize packaging quality, reduce labor dependency, and protect high-value reels throughout storage and logistics operations.

In modern factories, this machine functions as a critical end-of-line packaging solution, not a secondary accessory.

Why Is an Industrial Reel Roll Wrapper Important in Modern Industrial Operations?

Manufacturers handle larger, heavier, and more valuable reels than ever before. Manual wrapping cannot deliver the consistency, safety, or speed that modern operations require.

An industrial reel roll wrapper:

Eliminates uneven film tension and loose wrapping

Minimizes film waste through controlled pre-stretch

Protects reels from moisture, dust, and transit damage

Improves workplace safety by reducing manual lifting

Maintains uniform packaging standards for exports

In high-volume production environments, this machine directly supports operational efficiency, product quality, and cost control.

Which Technical Features Directly Improve Productivity and Quality?

PLC and HMI Control System

Operators store multiple wrapping recipes, ensuring repeatable packaging quality across different reel sizes.

Pre-Stretch Film Carriage

The machine stretches film before application, reducing film usage while increasing load stability.

Powered Rollers and Servo Drives

Controlled rotation prevents reel deformation and ensures precise tension control.

Automatic Film Cut and Clamp

This feature reduces cycle time and eliminates manual handling.

Edge Reinforcement Logic

Targeted edge wrapping prevents telescoping and impact damage during transport.

How Does the Machine Improve Safety and Cost Efficiency?

The machine:

Prevents reel slippage and collapse

Lowers packaging material consumption

Cuts labor costs per wrapped reel

Reduces product damage and rejection rates

Over time, these benefits offset the initial investment and deliver measurable ROI.

An Industrial Reel Roll Wrapper directly impacts product protection, production efficiency, operator safety, and packaging cost control. When selected correctly and configured to real factory conditions, it delivers long-term operational stability and competitive advantage in modern industrial environments.

Frequently Asked Questions (FAQ)

1. What materials can an industrial reel roll wrapper handle?

An industrial reel roll wrapper handles a wide range of reel materials, including paper reels, plastic film rolls, textile rolls, nonwoven rolls, aluminum foils, rubber rolls, and laminated materials. The machine adjusts film tension and wrapping patterns based on material sensitivity.

2. How does the machine prevent damage to soft or delicate reels?

The machine uses controlled rotation, adjustable film tension, and pre-stretch systems. These features prevent excessive pressure, surface marks, and deformation, even on soft or delicate reel materials.

3. What type of wrapping film does the machine use?

The machine uses stretch film as standard, but it also supports LDPE film, protective sheets, and laminated wrapping materials depending on product and export requirements.

4. Can one reel roll wrapper wrap different reel sizes?

Yes. The machine accommodates multiple reel diameters and widths through adjustable rollers, sensors, and PLC-based recipes. Operators can switch between sizes without mechanical changes.

5. What is the difference between semi-automatic and fully automatic reel roll wrappers?

A semi-automatic reel roll wrapper requires operator involvement for loading and unloading, while a fully automatic system integrates with conveyors and production lines, reducing labor and increasing throughput.