Vertical Coil Packing Machine

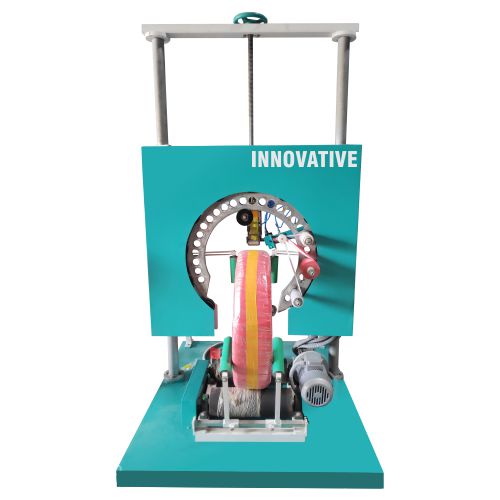

A Vertical Coil Packing Machine is an industrial packaging system designed to wrap metal coils in a vertical (eye-to-sky) orientation using stretch film, LDPE film, or VCI corrosion-protection film.

The machine stabilizes the coil on a rotating turntable while an orbital wrapping ring applies controlled film layers around the coil’s circumference and width.

Manufacturers use vertical coil packing machines to protect steel, aluminum, copper, and wire coils from moisture, dust, surface damage, and handling impact during storage and transportation.

How Does a Vertical Coil Packing Machine Work?

Coil Loading

The operator loads the coil vertically onto the turntable using a crane, C-hook, or forklift.Coil Positioning and Centering

Guide rollers and centering arms align the coil to prevent vibration and uneven rotation.Film Installation and Parameter Setup

The operator installs the film roll in the carriage and sets wrapping speed, overlap ratio, and tension.Cycle Start Command

The operator starts the wrapping cycle via PLC-HMI or control panel.Turntable Rotation

The turntable rotates the coil at a controlled speed to maintain stability.Orbital Ring Wrapping

The wrapping ring rotates around the coil, applying film evenly across the coil surface.Layer and Overlap Control

The system ensures uniform coverage with adjustable overlap for export or long-term storage protection.Film Cut and Clamp

The machine cuts and clamps the film automatically or semi-automatically.Coil Unloading

The wrapped coil exits the station, ready for storage, strapping, or dispatch.

Why Is a Vertical Coil Packing Machine Important in Modern Industrial Operations?

Modern metal industries demand high packaging consistency, damage prevention, and labor efficiency. Vertical coil packing machines deliver these benefits by:

Reducing manual handling and labor dependency

Preventing corrosion and surface damage

Ensuring repeatable packaging quality

Increasing throughput without compromising safety

Supporting lean manufacturing and export compliance

In high-value metal production, improper coil packaging directly causes rejections, customer complaints, and logistics losses. This machine eliminates those risks.

What Are the Installation Requirements and Best Practices?

Installation Requirements

Flat industrial flooring

Proper electrical grounding

Adequate clearance for coil handling

Crane or forklift access

Best Practices for Operation

Use correct film grade and thickness

Adjust tension based on coil material

Follow standard startup and shutdown procedures

Frequently Asked Questions (FAQs)

Q1. What is a vertical coil packing machine used for?

A vertical coil packing machine is used to pack metal and wire coils in an upright position using stretch film or protective materials. It protects coils from moisture, dust, corrosion, and mechanical damage during storage and transportation.

Q2. Which types of coils can be packed using a vertical coil packing machine?

The machine is suitable for steel coils, wire coils, aluminum coils, copper coils, stainless steel coils, and other round or ring-shaped industrial products.

Q3. How does a vertical coil packing machine work?

The coil is placed vertically on the machine platform. The wrapping ring rotates around the coil while applying film with controlled tension and uniform overlap. After wrapping, the film is cut and secured before coil discharge.

Q4. What packaging materials are supported by this machine?

The machine supports stretch film, LDPE film, HDPE film, and VCI film depending on corrosion protection and packaging requirements.

Q5. Is the vertical coil packing machine available in automatic versions?

Yes, vertical coil packing machines are available in semi-automatic and fully automatic models, with options for PLC control, conveyor integration, and high-speed production.