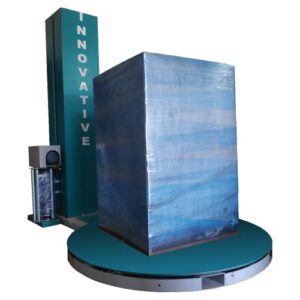

Pallet Stretch Wrapping Machine

A Pallet Stretch Wrapping Machine is an industrial packaging machine used to wrap palletized products with stretch film for safe storage and transportation.

It improves load stability, protects products from external damage, and helps reduce stretch film usage through controlled wrapping.

What is a Pallet Stretch Wrapping Machine?

A Pallet Stretch Wrapping Machine is used in industries to securely wrap palletized products with stretch film.

The machine ensures uniform film tension and proper coverage around the pallet, making the load stable and secure during handling and transit.

It provides:

Packing strength

Protection from dust, moisture, and pilferage

Reduced film consumption

This machine is ideal for warehouses, factories, and logistics operations where pallet stability is critical.

Types of Pallet Stretch Wrapping Machines

We manufacture seven main types of pallet wrapping machines:

1. Manual Type Pallet Wrapping Machine (PIM01)

This is a low-cost pallet wrapping machine suitable for small-scale operations.

In this model, only the turntable rotates automatically, while the film up-down movement is done manually by the operator.

Features:

Automatic turntable rotation

Manual film up/down system

Advantages:

Compact design

Budget-friendly

Easy to move

Disadvantages:

Limited film saving

Manual operation required

2. Pallet Wrapping Machine with Ramp (PIM02)

This is one of the most preferred pallet wrapping machines among industrial users.

The ramp allows easy loading and unloading of pallets using forklifts or stackers.

Features:

Photo-eye sensor for height detection

Heavy-duty turntable structure

PLC-controlled operation

VFD motors for speed control

Disadvantages:

Manual stacker may require at least two operators

Electric stacker is recommended for smooth operation

3. Pallet Wrapping Machine with Holding System (PIM03)

This machine is designed for lightweight products that may shift or fall due to film tension during wrapping.

It is suitable for product weights ranging from 10 kg to 150 kg.

Applications:

Water tank industry

Low-weight corrugated box industry

Types of Holding System:

Motorized holding system

Pneumatic holding system

4. Pallet Wrapping Machine with Auto-Cutting System (PIM06)

This model works similar to the ramp type pallet wrapping machine but includes an automatic film mounting and cutting system.

It significantly reduces manual effort and improves wrapping speed.

Advantages:

Time-saving operation

Reduced labor requirement

5. M-Type Pallet Wrapping Machine (PIM04)

This machine is ideal when loading and unloading are done using a manual stacker by a single operator.The M-shaped cut under the turntable allows easy pallet entry without lifting the load.

6. Arm Type Pallet Wrapping Machine (PIM05)

In this machine, the pallet remains stationary while the wrapping arm rotates around it.

This design eliminates the need for a turntable and simplifies loading and unloading.

Advantages:

Easy handling of pallets

Space-saving design

7. Arm Type Pallet Wrapping Machine with Conveyor System (PIM07)

This model is suitable for high-production environments where pallets move through conveyors.

The pallet enters through the infeed conveyor, gets wrapped at the station, and exits through the outfeed conveyor.

Advantages:

Fast and continuous packing

Easy handling

Reduced labor cost

Features of Pallet Stretch Wrapping Machines

High-quality construction

Up-Down system for covering maximum pallet size

Pre-stretch system (up to 250% stretch)

AC motor with frequency inverter control

Separate Start / Reset / Emergency Stop buttons

Heavy-duty chain drive

Turntable always stops at home position

One-touch automatic programs + manual run option

Advanced photo-eye sensor to detect package height

Easy-to-load stretch film unit

Innovative Feature:

Power pre-stretch system for 50–90 micron film stretched up to 300%

Specifications

Stretching Type: Pre-Stretch

Control System: PLC Controller

Turntable Diameter: 1650 mm

Maximum Pallet Weight: 2500 kg

Maximum Load Height: 2500 mm

Working Size: 1200 x 1200 mm

Power: 3 HP

Advantages

Protects from dust, moisture, and foreign particles

Prevents pilferage

Provides pallet stability

Scratch resistance

Easy and fast handling

Economical packing

Frequently Asked Questions (FAQs)

How much does it cost to stretch wrap a pallet?

Depends on pallet size and film usage.

Example: Pallet 1000x1000x1000 mm uses 200–300 gm of film → ₹25–35 (~$0.35–0.40 USD)

How much does an automatic pallet wrapper cost?

Depends on pallet size and model.

Ramp model: $4250–$7500 (~₹3,00,000–5,00,000)

How many times should a pallet be wrapped?

Depends on film strength.

Example: For 23-micron film, minimum 3 turns at bottom and top, keeping film tight

How many pallets can be wrapped per hour?

Normal size pallet: 30–35 pallets per hour

What is the maximum pallet size this machine can wrap?

Customizable; maximum: height 3.5 m, width 1.8 m, length 1.8 m

Which type of stretch film can be used?

Manual grade (low performance)

Machine grade (recommended: minimum 23-micron, 20-inch width)