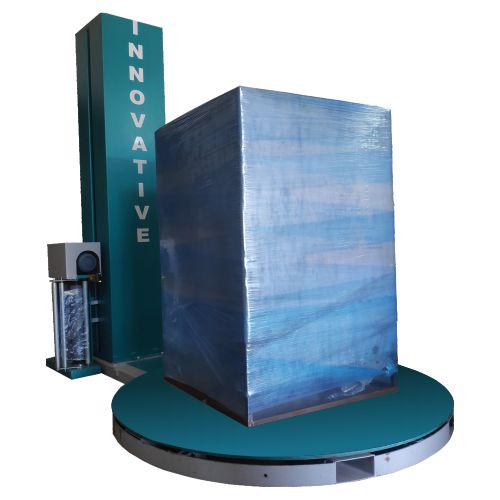

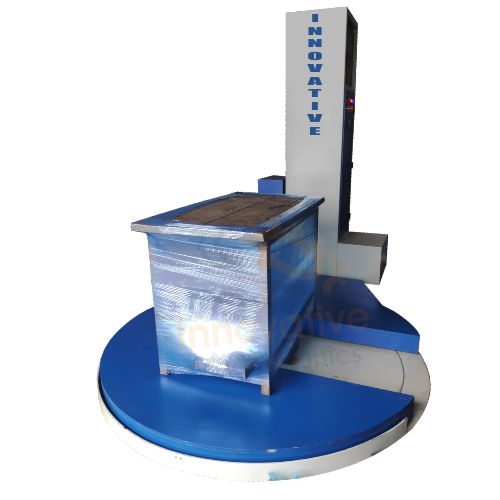

Arm Type Pallet Wrapper

An Arm Type Pallet Wrapper is an advanced pallet wrapping machine designed to stabilize palletized loads by rotating a wrapping arm around a stationary pallet. Unlike turntable machines, the pallet remains fixed while the arm applies stretch film uniformly.

Innovative WrapTech Pvt. Ltd. engineers arm type pallet wrappers for high-speed, heavy-duty, and automated industrial packaging environments where load stability, safety, and efficiency are critical.

How an Arm Type Pallet Wrapper Works

Pallet Positioning

The pallet is placed on the floor or conveyor system without movement.Film Attachment

The stretch film is automatically or semi-automatically attached to the pallet base.Rotating Arm Movement

The wrapping arm rotates around the stationary pallet at controlled speed.Vertical Film Carriage Travel

The film carriage moves upward and downward to apply layered wrapping.Pre-Stretch Film Application

Pre-stretch rollers extend the film to reduce consumption while increasing load tension.Film Cutting & Sealing

The system cuts and seals the film automatically at the end of the cycle.Wrapped Pallet Discharge

The wrapped pallet exits safely via conveyor or forklift.

This process ensures consistent wrapping regardless of pallet weight or stability.

Installation, Operation & Maintenance Best Practices

Installation

Confirm electrical compliance

Allow adequate safety clearance

Operation

Use high-quality stretch film

Select correct wrap program

Train operators on HMI controls

Maintenance

Weekly inspection of belts and rollers

Lubricate moving parts regularly

Periodic PLC and sensor diagnostics

Preventive maintenance ensures high uptime and long machine life.

Safety Standards, Compliance & Operator Protection

Innovative WrapTech machines comply with:

ISO manufacturing standards

CE safety norms

Emergency stop switches

Safety fencing and interlocks

Load presence and motion sensors

These features minimize workplace accidents and ensure regulatory compliance.

Why Manufacturers Choose Innovative WrapTech Pvt. Ltd.

Proven industrial engineering expertise

Custom-built automation solutions

Reliable after-sales support

Long-term ROI and durability

Manufacturers trust Innovative WrapTech for scalable, future-ready packaging systems.

Frequently Asked Questions (FAQs)

Q1. Can an arm type pallet wrapper handle very heavy loads?

Yes. Since the pallet remains stationary, there is no weight limitation.

Q2. Is this machine suitable for unstable products?

Absolutely. It is ideal for fragile, tall, or uneven pallets.

Q3. How much film does it save compared to manual wrapping?

Pre-stretch systems reduce film usage by up to 40%.

Q4. Can it integrate with conveyors and ERP systems?

Yes. Fully automatic models support conveyor and smart factory integration.

Q5. What is the expected machine lifespan?

With proper maintenance, 10–15 years of reliable operation is typical.