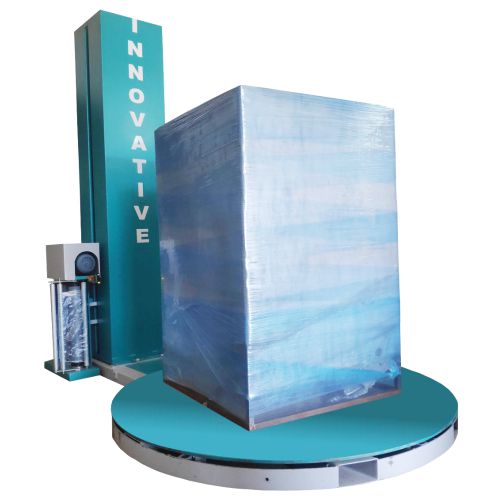

Box Wrapping Holding System – Complete Industrial Packaging Solution

The Box Wrapping Holding System is an advanced industrial machine designed to secure cartons and boxes during stretch wrapping. Its built-in holding mechanism stabilizes boxes on pallets, prevents shifting, and ensures consistent, high-quality packaging. This system is essential for modern industrial operations where speed, efficiency, and damage reduction directly impact profitability.

Why This Machine Is Critical in Modern Industrial Operations

Reduces Product Damage: Stabilizes loads to prevent shifting and crushing during transport.

Improves Efficiency: Automates a process that is slow and inconsistent if done manually.

Lowers Labor Costs: One operator can manage multiple pallets simultaneously.

Ensures Consistency: Delivers uniform wrapping for professional presentation and compliance.

Supports High-Volume Operations: Essential for warehouses, logistics centers, and production lines.

Types and Variants

| Type | Description | Best Use Case | Advantages |

|---|---|---|---|

| Semi-Automatic Holding System | Operator initiates wrapping cycle | Small to medium production | Lower cost, flexible operation |

| Fully Automatic Holding System | Integrated with conveyors, automatic cycles | High-volume factories | Minimal labor, higher throughput |

| Rotary Arm Holding System | Arm rotates around stationary pallet | Tall or irregular loads | Stable wrapping for delicate or uneven products |

Installation, Operation, and Maintenance Best Practices

Installation:

Place on a level, sturdy floor with adequate clearance.

Connect to a stable power supply and ensure grounding.

Test all sensors and safety interlocks before production.

Daily Routine:

Inspect film carriage and rollers.

Clean dust and debris from moving parts.

Check safety stops and sensor functionality.

Weekly Routine:

Lubricate moving components.

Verify tension settings and alignment.

Inspect belts, chains, and mechanical connections.

Long-Term Maintenance:

Perform system calibration and software updates if automated.

Conduct full safety audits every 6–12 months.

Why Manufacturers Prefer Professional-Grade Machines

Higher durability and longer service life.

Consistent performance in high-volume operations.

Lower maintenance and downtime.

Safer for operators compared to low-cost alternatives.

Integrated automation and smart factory compatibility.

Future Trends and Automation Possibilities

Integration with ERP and warehouse management systems for automated tracking.

Remote monitoring for predictive maintenance.

Smart sensors and IoT-enabled automation for Industry 4.0 factories.

Potential for multi-pallet simultaneous wrapping in advanced production lines.

The Box Wrapping Holding System by Innovative WrapTech Pvt. Ltd. offers secure, efficient, and safe carton wrapping for modern industrial operations. It reduces damage, saves labor, and improves throughput. Available in semi-automatic, fully automatic, and rotary arm variants, the machine suits a wide range of industries. Buyers seeking durable, high-performance, and ROI-focused packaging solutions will find this machine essential for both current operations and future smart factory integration.

Frequently Asked Questions (FAQ)

Q1: What are the energy and power requirements of this machine?

The Box Wrapping Holding System operates on 220V single-phase or 380V three-phase power and uses energy-efficient motors to reduce electricity consumption and operational costs.

Q2: Can the machine handle different box sizes?

Yes, the machine supports multiple box sizes with adjustable holding and film tension settings, ensuring secure and uniform wrapping for every load.

Q3: How long is the expected service life of the machine?

With proper operation and maintenance, the machine lasts 10–15 years, offering a strong long-term return on investment.

Q4: Is operator training required?

Yes, basic operator training ensures safe handling, proper loading, and efficient operation of the machine.

Q5: Can the machine integrate with existing production lines or ERP systems?

Yes, fully automatic models integrate seamlessly with conveyor systems, production lines, and ERP setups, enabling automation and smart factory applications.