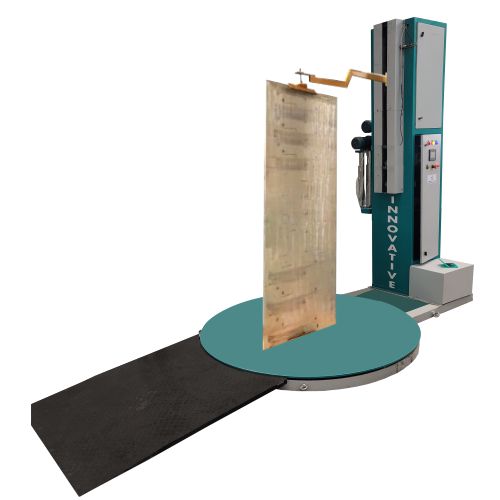

Pallet Wrapping Machine For- Door Packing

However, we make pallet stretch wrap machine also called pallet packing machine manufacturer in India. we also export in USA, UAE, Dubai and South Africa, etc

About stretch wrapping machine manufacturers

Pallet wrapper use to packing product with a stretch film like chemical industries use, paper industries use However, steel industries, food industries and also use in pharma industries.

many types of pallet wrapping machines

however, mainly 5 types of pelet packing machine running in industries. please check that all type of pallet film packing machine .

Above all, it’s all types of different industries use according to his production.

- Rottary Arm Type wrapping machine

- M-type Palller wrapper machine

- manual pallet packer machine

- automatic packing machine with film cutting system

- fully automatic pallet wrapping with conveyor system

pallet stretch wrapping machine risk assessment

However,In Different industries, rink assessment is different like

chemical industries use all electronics goods use Ip 66 with panel.

other industries use bari-gate outside of wrapper machine in India pallet stretch wrapping machine risk assessment

In addition some companies use cutter sensor for protecting man, it provides pallet packer machine manufacturer in India

mobile pallet wrap machine

However, use mobile pallet wrapper use to small industries. like him production is very less . mobile pallet packing also called manual pallet machine.

automatic pallet stretch wrapping machine price

Above all, if need film cutting system than use automatic pallet film wrapping machine.

- In addition, High efficiency and low electricity-consumption, convenient in operation.

- The wrapping type and times can be designed on customers’ requirements.

- Auto-pallet height detection.

- Auto reset of turn table pallet stretch wrapping machine manufacturer.

- However,HL-2100P with top press.

- HL-2100D with remote control.

- Programmable control and frequency converter is available.

- Optional function: Remote control; Pneumatic controlled film feeding & cutting system

Best manufacturer in India

In this paragraph, many manufacturers in India but need the best quality and best price with high than purchase machines from Innovative mechatronics.

however, spiral wrapping machine mini packing machine group companies of innovative tech is one of the best companies in Indian.

innovative group Similarly, export machines in USA, Egypt, Sout Africa, Kenya UAE, Australia, rasiya, Sri Lanka, Pakistan, China, Indonesia, Vietnam, Poland, France, Dubai, Canada, Brazil, Bolivia, Chile, Cyprus, Qatar, Israel.

Similarly, Innovative Group supply many more countries like

Uganda, United Arab Emirates, United Kingdom, Vietnam, Kingdom of Serbia, Kuwait, Spain, Philippines, Oman, Nigeria, Nepal, New Zealand, Mexico etc..

International quilty

*An ISO and CE certified company.

*Expert manufacturer with more than 10 years’ experience in the coil packing field.

*Above all, reliable and high-quality coil wrap machine.

*Providing custom-built hose packing machines according to special requirements packing machine.

*Above all, Providing updates and on-time technical support.